1.i-pet resinintshayelelo

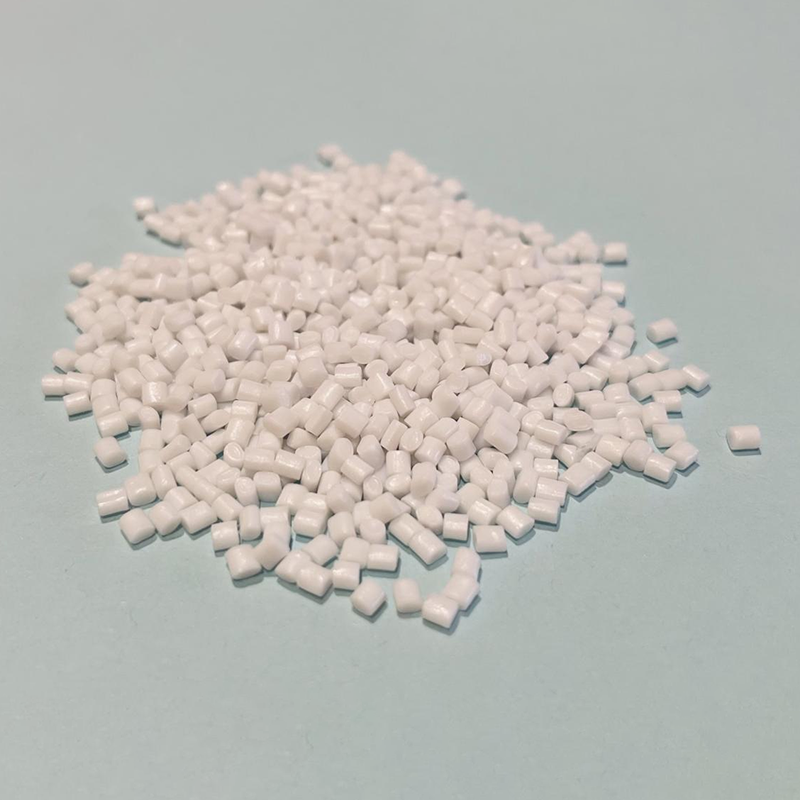

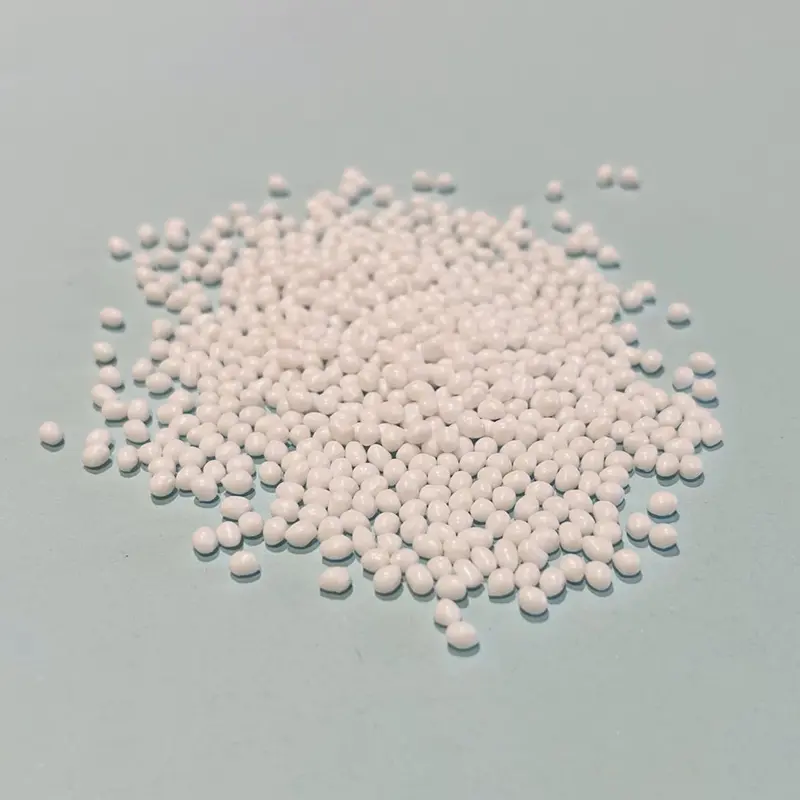

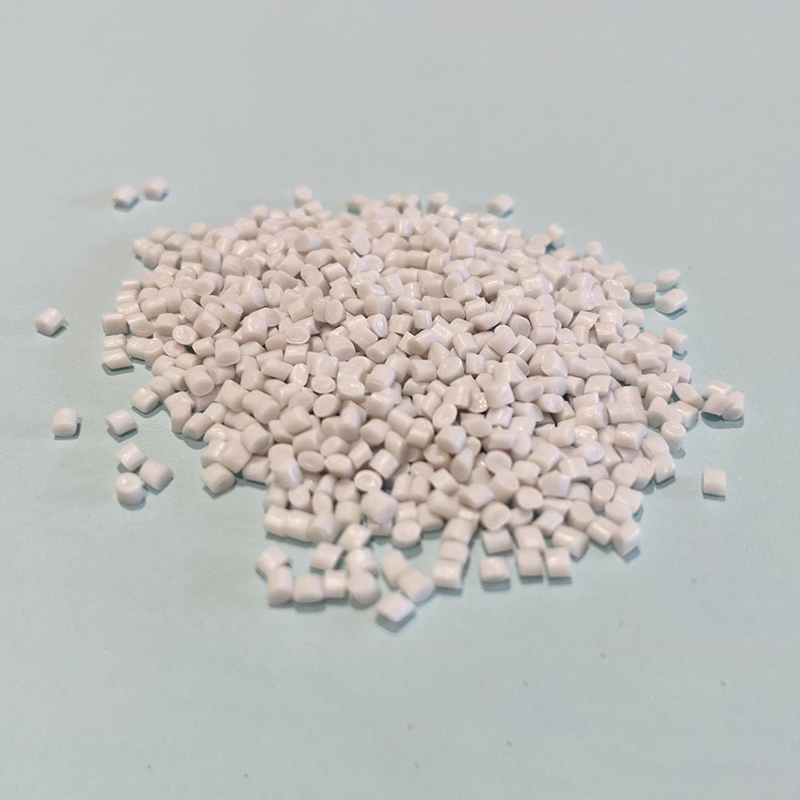

Igama lekhemikhali ye-PET I-Polyethylene terephthalate, eyaziwa ngokuba yi-polyester, ifomula yeekhemikhali COC6H4COOCH2CH2O.I-Dihydroxyethyl terephthalate yalungiswa nge-transesterification ye-dimethyl terephthalate kunye ne-ethylene glycol okanye i-esterification ye-terephthalate nge-ethylene glycol, kwaye emva koko i-polycondensation reaction.Yi-crystalline saturated polyester, emhlophe ebisi okanye etyheli ekhanyayo, ipholima ekhazimle kakhulu enomgangatho ogudileyo nomenyezelayo.I-resin eqhelekileyo ebomini kwaye inokwahlulwa ibe yi-APET, RPET kunye ne-PETG.

I-PET lubisi olumhlophe okanye olutyheli olukhanyayo, ipholima ekhazimle kakhulu enomgangatho ogudileyo, umenyezelayo.Ineempawu ezibalaseleyo zomzimba kunye noomatshini kuluhlu olubanzi lobushushu, ubushushu bokusebenzisa ixesha elide ukuya kuthi ga kwi-120 ℃, ukugqunywa kombane okugqwesileyo, nokuba kubushushu obuphezulu kunye nobushushu obuphezulu, iipropathi zayo zombane zisalungile, kodwa ukunganyangeki kwe-corona, ukumelana nokunyuka, ukuxhathisa ukudinwa, ukuxhathisa ukukhuhlana, ukuzinza kwe-dimensional kuhle kakhulu.I-PET ine-ester bond, ukubola kuya kwenzeka phantsi kwesenzo se-asidi eqinile, i-alkali enamandla kunye ne-steam yamanzi, ukuchasana ne-solvents ye-organic, ukumelana nemozulu elungileyo.

Iimpawu ze-2.resin

I-PET inokumelana nokuhamba kakuhle, ukumelana nokudinwa, ukuxhathisa ukungqubana kunye nokuzinza komda, ukunxiba okuncinci kunye nokuqina okuphezulu, kwaye inokuqina okukhulu kwi-thermoplastics: ukusebenza kakuhle kokufakelwa kombane, impembelelo encinci ngamaqondo obushushu, kodwa ukunganyangeki kwe-corona.I-Non-toxic, ukumelana nemozulu, ukuzinza okulungileyo ngokuchasene neekhemikhali, ukufunxa kwamanzi aphantsi, ukuxhathisa kwii-asidi ezibuthathaka kunye nezinyibilikisi ze-organic, kodwa kungekhona ukuntywiliselwa kwamanzi okuxhathisa ubushushu, kungekhona ukuxhathisa kwe-alkali.

PET resininobushushu obuphezulu beglasi etshintshayo, isantya sekristale esicothayo, umjikelo omde wokubumba, umjikelo omde wokubumba, ukushwabana okukhulu kokubumba, ukuzinza okungalunganga komgangatho, ukubumba icrystallization emdaka, ukumelana nobushushu obuphantsi.

Ngokuphuculwa kwee-nucleating agents kunye ne-crystallizing agents kunye ne-glass fiber reinforcement, i-PET inezi mpawu zilandelayo ngaphandle kweempawu ze-PBT.

1. Ubushushu bokutshintsha kwe-Thermal kunye nobushushu bokusebenzisa ixesha elide zezona ziphezulu kwiiplastiki zobunjineli jikelele ze-thermoplastic.

2. Ngenxa yokumelana nobushushu obuphezulu, i-PET ephuculweyo ifakwe kwi-10S kwindawo yokuhlambela i-solder kwi-250 ° C, phantse ngaphandle kokuguqulwa okanye i-discoloration, eyona nto ifaneleke ngakumbi ukulungiswa kwamacandelo e-elektroniki kunye nombane we-solder welding.

3. Amandla okugoba yi-200MPa, i-elastic modulus yi-4000MPa, ukuxhathisa kwe-creep kunye nokudinwa kwakhona kuhle kakhulu, ubunzima bomhlaba buphezulu, kwaye iimpawu zomatshini zifana neeplastiki ze-thermosetting.

4. Ekubeni ixabiso le-ethylene glycol elisetyenziselwa ukuveliswa kwe-PET liphantse lisiqingatha se-butanediol elisetyenziselwa ukuveliswa kwe-PBT, i-PET resin kunye ne-PET eqinisiweyo yixabiso eliphantsi kakhulu phakathi kweeplastiki zobunjineli kwaye zinexabiso eliphezulu lokusebenza.

Ukuphucula iipropati ze-PET, i-PET inokudityaniswa ne-PC, i-elastomer, i-PBT, iklasi ye-PS, i-ABS, i-PA.

I-PET (i-PET ephuculweyo) icutshungulwa ngokukodwa ngokubumba i-injection, kunye nezinye iindlela zibandakanya i-extrusion, i-blow molding, i-coating kunye ne-welding, ukutywinwa, ukutshiza, i-vacuum coating kunye nezinye iindlela zokucutshungulwa kwesibini.Yomisa kakuhle phambi kokuba wenze.

I-Polyethylene terephthalate ilungiswe yi-transesterification ye-dimethyl terephthalate kunye ne-ethylene glycol okanye i-esterification ye-terephthalate nge-ethylene glycol, kwaye emva koko i-polycondensation reaction.I-crystalline saturated polyester, i-avareji ye-molecular weight (2-3) × 104, umlinganiselo we-avareji yobunzima ukuya kwinani eliqhelekileyo lobunzima be-molecular yi-1.5-1.8.

Iqondo lobushushu beGlasi yi-80℃, ukuxhathisa ubushushu kweMartin 80℃, ubushushu bokutshintsha kwe-thermal 98℃(1.82MPa), ubushushu bokubola yi-353℃.Ineempawu ezibalaseleyo zoomatshini.Ukuqina okuphezulu.Ubunzima obuphezulu, ukufunxwa kwamanzi amancinci, ukuzinza okuhle kwe-dimensional.Ukuqina okulungileyo, ukuxhathisa impembelelo, ukuxhathisa ukukhuhlana, ukuxhathisa ukukhwela.Ukumelana neekhemikhali ezilungileyo, i-soluble kwi-cresol, i-sulfuric acid egxininisiweyo, i-nitrobenzene, i-trichloroacetic acid, i-chlorophenol, i-insoluble kwi-methanol, i-ethanol, i-acetone, i-alkane.Ubushushu bokusebenza -100 ~ 120℃.Ukugoba amandla 148-310MPa

Ukufunxwa kwamanzi 0.06%-0.129%

Amandla empembelelo 66.1-128J / m

Ubunzima be-Rockwell M 90-95

Ukwandiswa 1.8%-2.7%

3. iteknoloji yokucubungula

Ukusetyenzwa kwe-PET kunokuba yinaliti yokubumba, i-extrusion, ukubunjwa kokuvuthela, ukugquma, ukudibanisa, ukudibanisa, ukwenza i-electroplating, i-vacuum yokucoca igolide, ukuprinta.Oku kulandelayo kwazisa iindidi ezimbini.

1. Inqanaba lokutofa ① ukusetwa kobushushu: umlomo: 280 ~ 295 ℃, ngaphambili 270 ~ 275 ℃, ephakathi forging 265 ~ 275 ℃, emva 250-270 ℃;Isantya Screw 50 ~ 100rpm, ubushushu ngundo 30 ~ 85 ℃, ngundo amorphous yi 70℃, uxinzelelo ngasemva 5-15KG.② Uvavanyo lokumisa umswakama, ubushushu betyhubhu yezinto ezingama-240 ~ 280 ℃, uxinzelelo lwenaliti 500 ~ 1400 ℃, ubushushu bokubumba inaliti 260 ~ 280 ℃, ubushushu bomisa 120 ~ 140 ℃, thatha iiyure ezi-2 ~ 5.

2. Kwinqanaba lefilimu, i-resin ye-PET iyasikwa kwaye yomiswe kwangaphambili ukukhusela i-hydrolysis, kwaye i-amorphous sheet thick sheet ikhutshwe kwi-extruder kwi-280 ° C nge-T-mold, kwaye idrum yokupholisa okanye i-coolant iyacinywa. yigcine ikwimo ye-amorphous ye-tensile orientation.Ishiti elishinyeneyo liphinde libe yi-bidirectional yolulwe ngumenzi ukwenza ifilimu ye-PET.

Ukolula ixesha elide kukufudumeza iphepha elishinyeneyo ukuya kuma-86 ~ 87 ℃, kwaye kobu bushushu, yolule malunga namaxesha ama-3 ecaleni kwendlela yolwandiso lwenqwelomoya eshinyeneyo, ukuze ukujoliswa kwayo kuphucule iqondo lecrystallization ukufikelela kubushushu obuphezulu: Ubushushu obuguquguqukayo be-preheating ye-98 ~ 100 ℃, i-tensile ye-100 ~ 120 ℃, i-tensile ratio ye-2.5 ~ 4.0, kunye ne-thermal setting ye-230 ~ 240 ℃.Ifilimu emva kokwelula ngokuthe nkqo kunye ne-horizontal nayo ifuna ukubunjwa kobushushu ukuphelisa i-deformation yefilimu ebangelwa ukunweba kunye nokwenza ifilimu ngokuzinza okuhle kwe-thermal.

Ixesha lokuposa: Sep-05-2023